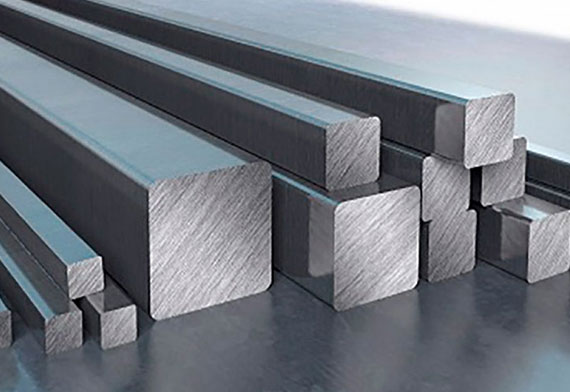

D.S. Metal supplies the widest range of square/flat Steel Bars for a multitude of applications in various grades like carbon steel, alloy steel(creep steel, case carburising, nitriding steel etc.), stainless steel and tool & die steel. The bars are straightened to remove any twist and give superior yields in the end product

The square/flat bars are made from ingots and are processed after giving required reduction ratio and discarding hot top and bottom for homogeneity. They are either processed by hot rolling or hot forging. These bars are further heat treated as per customer requirements by anyone of the following processes :

Following checks are conducted in bars and reported in the TEST CERTIFICATE as per customer requirements

Our batch size is minimum of 8.5MT so for common grades we can do 2 nearby sizes in total of 8.5MT and in case of special grades we require a single size minimum of 8.5MT.

| Process | Size (mm) |

| Hot Forged Flats | 450x100 - 400x450 |

| Hot Forged Squares | 125x125 to 400x400 |

| Hot Rolled Flats | 30x6 - 440x50 |

| Hot rolled squares | 20x20 to 55x55 |

| Hot Rolled RCS (Round Cornered Squares) | 60RCS - 160RCS |